| |

Wire Cutting

Wire Cutting |

|

|

|

|

|

Wirecut EDM Service

Classic

Tool & Die Inc. is not just a

preferred metal stamping die

supplier, but is also a valuable source

for customers with Wire-Cut EDM

needs. In 1984, Classic Tool & Die

pioneered wire cut EDM service in

Southern Ontario. Today, more than

ever, we understand the demands you

face to produce larger and more

complex components. Classic, the

most experienced in EDM wire

cutting, can accommodate your oversized work pieces, using

machines with the largest cutting

capacity available in North

America. Don’t let your customers’

larger tooling requests limit your

options to conventional machining.

Call us for solutions. We

offer the largest Wire EDM capacity

to meet tomorrow’s challenges today.

|

DIES

|

|

MOLDS

|

|

DETAILS

|

|

PROTOTYPES

|

|

LOW/HIGH VOLUME PRODUCTION

|

Give us

any work piece of conductive

material, soft or hardened,

including carbide and titanium, and

let us put our system to work for

you. With the best technology to

cut material in two or four axis

with a Z height of up to 20”, the

possibilities are endless. We can

generate cutter paths from customer

CAD data, print, or your part may be

digitized from a sample. Give us

your biggest, we’ll give you our

best. |

Machine Capacities

Classic Tool & Die offers 3 wire EDM machines to suite

any

requirement:

|

Hitachi 8Q

One of the largest wire

EDMs in North America

Max work

piece:

X 57" Y 41" Z 20"

Table stroke:

40" X 32"

Max weight capacity:

4,400 lbs.

Max taper angle:

7.875" +/- 12

deg |

|

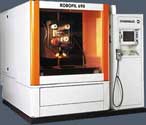

Charmilles Robofil 690

First 690 commissioned

in North America

Max work

piece: X 54" Y 39" Z 16"

Table stroke:

31.5" x

23.5"

Max weight capacity:

4,410 lbs.

Max taper angle:

4.375" +/- 15

deg

|

|

Fanuc P Series

First wire EDM utilized

in southern

Ontario

Max work

piece: X 25" Y 30" Z 8"

Table stroke:

14"

x 10"

Max weight capacity:

352 lbs.

Max taper angle:

4" +/- 10 deg

|

Maximum Taper Capabilities:

Workpiece Height

Maximum Angle

|

|